Sheet Metal Fabrication

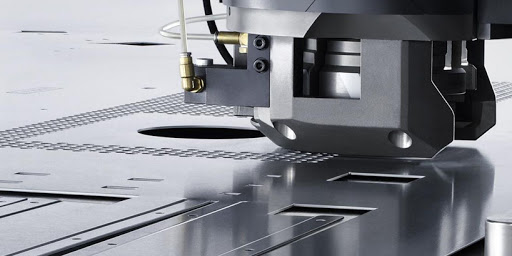

Laser Cutting

Laser cutters produce metal parts from sheets, using a laser beam to vaporize sections of the workpiece.

Laser cutting offers several advantages over traditional mechanical cutting or CNC machining processes, including quicker production, decreased waste of the raw material, and reduced chance of warping. Laser cutting produces clean cuts and has a small chance of operator error making them great for rapid prototyping.

Laser cutting offers several advantages over traditional mechanical cutting or CNC machining processes, including quicker production, decreased waste of the raw material, and reduced chance of warping. Laser cutting produces clean cuts and has a small chance of operator error making them great for rapid prototyping.

Plasma Cutting

Plasma cutters use a high velocity stream of ionized gas to cut shapes out of sheet metal.

Plasma cutters are a good all-around sheet metal fabrication tools, though they lack the material cutting diversity of waterjet machines and don’t have the precision of laser CNC machines .

For larger sheet metal parts, plasma cutters are more cost-efficient than CNC laser machines and can cut thicker materials easily. in addition to operate and cut at high speeds while maintaining precision

Plasma cutters are a good all-around sheet metal fabrication tools, though they lack the material cutting diversity of waterjet machines and don’t have the precision of laser CNC machines .

For larger sheet metal parts, plasma cutters are more cost-efficient than CNC laser machines and can cut thicker materials easily. in addition to operate and cut at high speeds while maintaining precision

Waterjet Cutting

Waterjet technology is basically the flow of water to the pump which then reaches pressures up to 100,000 psi and through high pressure tubing and out to the cutting head.

One of the advantages that waterjets have is no melting or heat affected zones. There is no heat distortion and it does not change the properties of the material.

Another major advantage is that waterjets cut at much lower temperatures. Waterjets cut a wider range of various materials especially materials such as granite, plastics, or laminates that are destroyed by melting.

One of the advantages that waterjets have is no melting or heat affected zones. There is no heat distortion and it does not change the properties of the material.

Another major advantage is that waterjets cut at much lower temperatures. Waterjets cut a wider range of various materials especially materials such as granite, plastics, or laminates that are destroyed by melting.

CNC punching

These machines can be either a single head and tool rail design or multi-tool turret type . The CNC punching machine is basically programmed to move a workpiece in an x and y directions to accurately position the sheet under the machine’s punching ram ready to punch a hole or form.

The processing range for most CNC punch presses is 0.5mm to 6.0mm thick in a range of materials including steel, galvanize, stainless steel and aluminum. The choice of hole punched can be as simple as a circle or rectangle right through to special shapes to suit a specific cut.

Bending and welding

Bending is an economical method of producing 3D parts from metal sheets. Bent sheet metal parts are commonly made using a pneumatic or hydraulic press, where a workpiece is pressed between a punch and die to bend it to the desired angle or shape.

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is usually used on metals and thermoplastics . The completed welded joint may be referred to as a weldment.

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is usually used on metals and thermoplastics . The completed welded joint may be referred to as a weldment.